Could you briefly present your profession and activity, and the REUT project developed in Nice?

“My name is Pierre Geeraert. I'm a project manager at Nomado, a 25-strong SME specializing in containerized water treatment units. We work in drinking water production, urban wastewater treatment, industrial effluent treatment and, increasingly, water recycling.

We are based in Marseille, and we are developing projects all over the world.

For the city of Nice, we have set up a water recycling system at the wastewater treatment plant, using a 40-foot container that produces an average of 12 m3/hr.

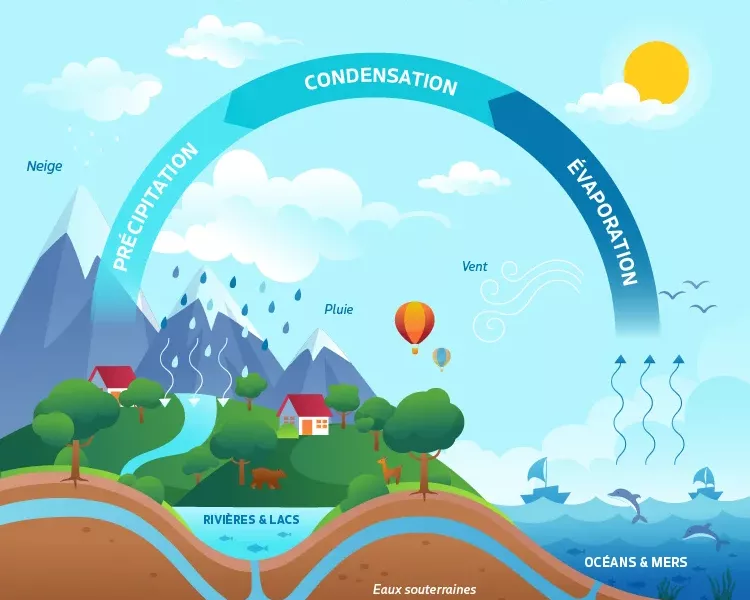

The aim of the project is to recover treated wastewater before it is discharged into the sea, and insert it into a treatment cycle so that it can be reused for other purposes. The city of Nice wanted a pilot plant to test the processes, as they are part of a large-scale water recycling project.

So the city wanted to set up a pilot plant to test water treatment technologies at the end of a wastewater treatment plant, because in France we don't yet have much experience of these processes and types of treatment, and in particular of the European standards that have recently been put in place.”